Just a few seats left: NDL digital leader roadtrip 2024

News about our NDL roadtrip 2024, program and tickets

Technological aids for continuous monitoring of the dairy herd are no longer a rarity. Many farmers now rely on the support of innovative sensor technologies on their farms. Probably one of the most revolutionary systems for monitoring dairy herds is bolus technology. But how does a bolus actually work? And what are the advantages over other methods and technologies?

In order to detect abnormalities, record animal health and manage calvings and rutting, close observation over a long period of time is unavoidable. However, the intensive care of each individual animal requires not only many years of experience and comprehensive knowledge, but also a lot of time – nowadays a scarce commodity.

Due to changing farm structures with a larger number of animals and fewer employees, increasing cost pressure, and time-consuming bureaucracy, farmers cannot always devote their full attention to their animals. Higher milk production per cow has also increased susceptibility to disease, which means that animals need more care. Technology provides relief – and the innovative smaXtec bolus technology a new standard in health monitoring and prevention in dairy cows through continuous measurement.

The smaXtec system consists of the sensors in bolus form and readout devices placed in the barn. A bolus is administered orally to each animal. A bolus injector is used for this, as with the input of other boluses such as calcium boluses. The boluses land in the reticulum, where they remain for the life of the cow due to their own weight.

From the time of entry, the bolus continuously collects direct, informative and animal-specific data inside the cow, more precisely in the reticulum. Readout devices installed in the barn capture the bolus data and automatically transfer it to the smaXtec server. There, the unique data is processed into valuable information for farmers. Only electricity is required in the barn for data transmission, and the Internet is included.

Farmers access the processed information from their smartphone or computer, regardless of time and location. In this way, farmers always know how their animals are doing. In case of acute need for action, the system sends an e-mail and/or push message. This way, farmers always know how their animals are doing. If desired, farmers can also share the data, for example with their veterinarian, employees or family members. This way, everyone benefits from the valuable information and recommendations for action, and the workflow can be designed efficiently.

The smaXtec system is equally popular and valued for its profitability on 60-cow farms as it is on farms with 500 animals and more. More than 70,000 sensors have now been sold in over 25 countries.

Bolus technology has a number of advantages over other systems. Especially the measuring position brings enormous advantages. For example, internal body temperature, drinking behavior and rumen pH can be measured exclusively inside the cow. The position also allows measurement of high quality information without outside influences. Only high quality data provides accurate results and calculations. Therefore, it is important that the measurement sensor cannot be influenced from the outside. In addition, continuous measurement of the parameters at the same location enables comparability of the data obtained. This makes it easier to identify deviations from the normal state and to detect abnormalities more quickly. The bolus technology is also extremely practical in terms of handling: once entered, no further work is required on the animal in relation to the sensor. The system is completely maintenance-free, and there is no risk of loss or injury. This means both safety and a significant time saving for farmers.

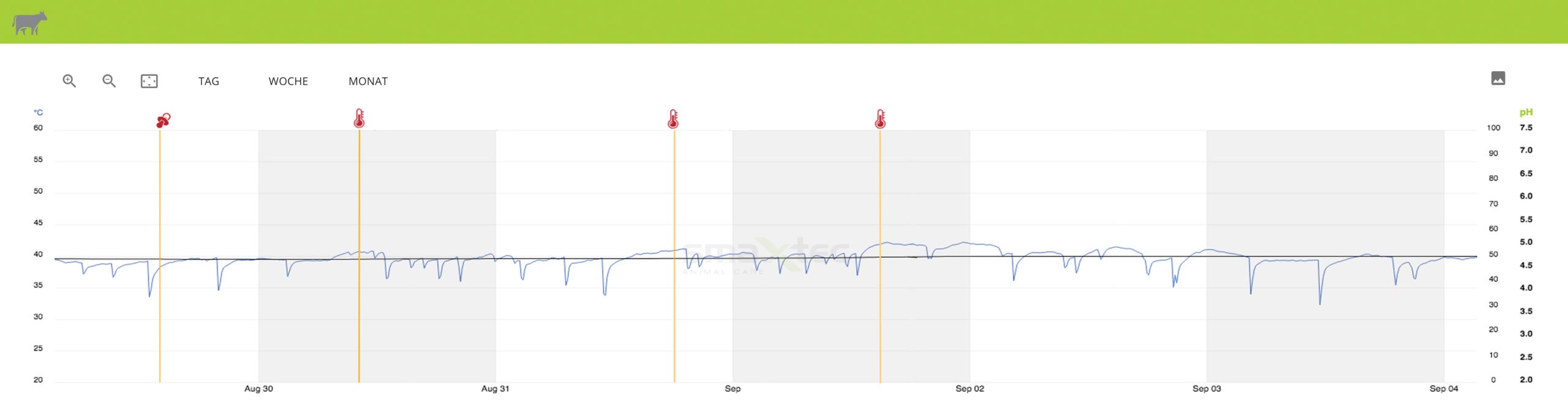

The most outstanding advantage of the bolus technology is the possibility to continuously measure the internal body temperature. This is valuable for a variety of applications: On the one hand, it is the best parameter for monitoring animal health and enables the earliest possible detection of diseases. Because as soon as the immune system reacts to pathogens or stress, the internal body temperature changes – long before external signs become visible! As a result, the system detects diseases such as mastitis up to 4 days before clinical symptoms become visible.

Monitoring animal health through temperature monitoring offers another advantage: depending on the temperature change, the farmer knows what to check the cow for. If the temperature rises, this is an indication of a febrile illness, infection or inflammation. A drop in temperature, on the other hand, is an indication of a metabolic disease such as milk fever or ketosis.

In addition, continuous measurement of internal body temperature enables early detection of calving. On average, the system informs farmers of the start of the birthing process as early as 15 hours before calving, allowing them to make all necessary preparations, make optimal use of the calving area and intervene if necessary.

smaXtec detects a short-term deviation of the body temperature from normal up to 4 days before clinical symptoms appear – in this case it is an inflammation of the udder.

Bolus technology allows farmers to measure highly informative and high-quality data – right inside the cow. This provides them with valuable information and recommendations for action. This knowledge helps them to significantly improve their farm in the areas of health, reproduction and feeding.

Just a few seats left: NDL digital leader roadtrip 2024

News about our NDL roadtrip 2024, program and tickets

Save your seat: NDL Meet Up & new digital Pitches coming up in Q4|2023

NDL Meet Up Conference 29’/30′ Nov. | Online Pitches with Agolin & Arla in Oct. & Dec.

Perfectly connected – the farm of the future

Simple and automated data networking and easy operability of agricultural software are what most farms want. But what is holding back interface building?

Copyright © 2023 NDL. All rights reserved. | Privacy Policy | Imprint |

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information